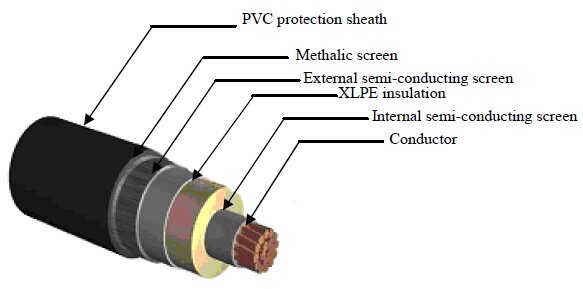

(Fig1-XLPE cable)

- Cable Sizing

- Minimum size of conductor

- Cable Sizing Example:

- Cables Impedance Calculation :

- Voltage Drop Calculation

- Short Circuit Calculation

- Cable Ampacity and Cable Sizing

- HOW TO CALCULATE WIRE AMPACITY

Cable Sizing

There are a various cables available in the market in various sizes. But, to decide which size will be appropriate for our application and requirement , we may require an Electrical Cable Size Calculator,selecting cable size as per our unique requirement is also called cable sizing. This helps us understand the best fit size for our requirement. It is calculated against IEC and British standards. A power factor of 0.8 is used in calculating The KW.

To calculate the Cable Sizing we need to divide the voltage running through the cable by the target current. For example, suppose If a wire has a voltage of 150 Volts and our target is 30A then we divide 150V/30A, this gives us our target resistance of 5 ohms which is required. Electrical Cable Size Calculator helps in calculating it in large numbers.

When we are searching for wires for our home and domestic lighting then usually 1.5mm or 1mm wire is used.

For cable sizing of power cable, the following factor should be considered :

a. Minimum size of conductor based on short circuit capacity

b. Allowable continuous current rating of cable

c. Allowable voltage drop cable

Minimum size of conductor

(1) The minimum size of conductor withstand a short circuit current shall be taken into considered following factor :

a) Maximum short circuit current

b) Maximum duration time of short circuit current

c) Under worst conditions, the conductor temperature shall not exceed its maximum short circuit temperature of 250 Deg C

(2) Calculation formula Formula given by the IEC 986 (Shown below) is used to select the minimum size of cable ( Cable Sizing).

I*t = K S ( θf + ß )/ ln (θi + ß)

The above equation can be simplified as S = I √ t / 143

Where ; I = maximum short circuit current ( r.m.s over duration ) in A

t = maximum duration time of short circuit current(S)

K = constant depending on material of conductor = 226 (AS ½ / mm2)

S = cross sectional area of conductor(mm-Sq)

Θf = final temperature of conductor = 250 ( Deg C)

Θi = initial temperature of conductor = 90 ( Deg C)

ß = reciprocal of temperature coefficient of resistance of conductor at 0 Deg C = 234,5

ln = log e

(3) The minimum of size of cable to 0.38 kV motor circuit shall be of 2.5 sq mm

(4) The minimum size of cable for equipment loads from Distribution Panel Boards ( minimum 6 A MCCB) shall be of 2.5 sq mm.

Cable Sizing Example:

Let’s say you need to size a cable for a 10 kW single-phase load operating at 230V with a power factor of 0.9.

- Calculate current:

I=10,000/ 230×0.9=48.3 Amps - Select Cable Based on Current: Based on tables for current-carrying capacities of different cables, choose a cable that can handle around 50A, considering any derating factors.

- Consider Other Factors: Apply correction factors for temperature, installation method, and allowable voltage drop to confirm the final cable size.

Cables Impedance Calculation :

Impedance is calculated by below formula:

𝑍𝑐=Squrt (𝑅𝑐^2+𝑋𝑐^2)

This method calculates the impedance when the cable and load power factor is the same, this scenario is worse case power factor.

cable sizing calculator uses the resistance Rc from Table 35 in AS/NZS 3008-2017. The reactance for single core cables is selected from the flat

Voltage Drop Calculation

The three phase AC voltage drop is calculated as below

𝑉𝑑3𝜙=𝐼*𝐿(Sqrt3*𝑍𝑐)/1000

The single phase AC voltage drop is calculated as below

𝑉𝑑1𝜙=𝐼𝐿(2𝑍𝑐)/1000

Where I is the load current, L is the distance, and Zc is the cable impedance in Ohm/km.

Short Circuit Calculation

The short circuit capacity of the cables is calculated according to AS/NZS 3008-2017

𝐼^2*𝑡=𝐾^2*𝑆^2

Where:

- I is the short circuit current capacity in amperes,

- K is a constant that is selected from Table 52 in AS/NZS 3008-2017.

- S is the cross sectional area of the conductor.

- t is the short circuit duration in seconds.

Cable Ampacity and Cable Sizing

Ampacity is defined as the maximum current, in amperes, that a conductor can carry continuously under the conditions of use without exceeding its temperature rating. Cable ampacity shall be at least 100 % of name plate rating full load current for motor and for non motor loads cable ampacity shall be at least 100 % maximum continuous load current.

Some problems associated if we overlook ampacity requirements may include risks for:

- Damage to the insulation: When heat exceeds the capacity of the insulation, it begins to damage it. Even if it doesn’t cause a fire, this damage can affect the performance of the wire, especially as it degrades over time.

- Electrocution: Exceeding ampacity also creates the risk of arc flashes and electrocution to electrical workers involved.

- Electrical fire: Excess heat can lead to fire hazards, which endanger property and anyone in the vicinity of the wiring.

HOW TO CALCULATE WIRE AMPACITY

Wire ampacity can be a complex calculation. Heat dissipation depends on a wide range of factors, notably ambient temperature and insulation material. This maximum temperature rating is primarily determined by insulation, and the temperature rating heavily influences the current-carrying capacity.

To calculate ampacity, we need to divide the device’s wattage by the cable’s rated voltage. This number will tell us the wire current capacities if the conductor’s temperature rises 30 degrees Celsius.

The calculation is simplified with the help of these ampacity charts. The actual equation looks like this:

- I = { ∆Φ – Wd[½T1+n(T2+T3+T4)] / RT1+nR(1+λ1)T2+nR(1+λ1+λ2)(T3+T4) }1/2

The calculation for ampacity requires the following information:

- I: The permissible current rating.

- ∆Φ (K): The rise in temperature for the conductor.

- n: The number of same-size conductors carrying the same load.

- R (Ω/m): The alternating current resistance for each unit length at the max operating temperature.

- Wd (W/m): The dielectric loss for each unit length for the conductor’s insulation.

- T1 (K m/W): The thermal resistance for each unit length between a conductor and the sheath.

- T2 (K m/W): The thermal resistance for each unit length of the bedding between the sheath and the armor in

- T3 (K m/W): The thermal resistance for each unit length of the cable’s external sheath.

- T4 (K m/W): The thermal resistance for each unit length between the cable’s surrounding medium and its surface.

- λ1: The ratio of losses in the metal sheath to the total losses in all cable conductors.

- λ2: The ratio of losses in the cable’s armoring to the total losses in all conductors of the cable.

Cable sizing calculator and Ampacity calculator are readily available and we only need to feed few data and it automatically calculates the values. All these calculations can be also done in ETAP (an electrical simulation software).

Cocnlusion

Cable sizing is crucial in electrical installations to ensure that the cables can carry the required current without overheating or suffering from excessive voltage drop. It involves determining the correct size of the cable based on various factors like current-carrying capacity, ambient temperature, type of insulation, method of installation, and length of the cable.