- Introduction to Transformer Construction

- What is a Transformer?

- Transformer Core

- Windings

- Types of Transformers

- Step-Up Transformers

- Step-Down Transformers

- Distribution Transformers

- Detailed Construction of Transformers

- Construction of transformer core

- Construction of transformer core

- Transformer Oil

- Transformer Tank and Bushings

- Cooling Mechanisms in Transformers

- Natural Cooling (ONAN)

- Forced Cooling (OFAF)

- Tap Changer in Transformer

- Off-load Tap Changer

- On-load Tap Changer

- Protective Devices and Accessories

- Buchholz Relay

- Pressure Relief Device

- Transformer Testing and Commissioning

- Common Transformer Faults and Maintenance

- Conclusion

- FAQs

Introduction to Transformer Construction

Transformers are one of the most critical components of electrical power systems. They play a crucial role in voltage regulation, allowing the safe and efficient transmission of electricity over long distances. This article will explore how Construction of transformer is done, their components, and their significance in maintaining reliable power distribution.

What is a Transformer?

A transformer is a device that transfers electrical energy between two or more circuits through electromagnetic induction. Its primary purpose is to increase (step-up) or decrease (step-down) the voltage in an electrical system, which ensures efficient transmission of power across various points in a grid.

Core Components of a Transformer

Transformers may look complex from the outside, but they are composed of a few key components that allow them to perform their vital role in power systems.

Transformer Core

The transformer core is perhaps the most critical part of the construction. It provides a pathway for the magnetic flux generated during the operation of the transformer. Typically, it is made from silicon steel laminated sheets to minimize energy losses caused by eddy currents.

- Importance of the Core: Without the core, the magnetic flux wouldn’t have a medium to flow through, making the transformer inefficient.

- Materials Used: Laminated silicon steel is used to ensure low hysteresis loss and minimal eddy current losses.

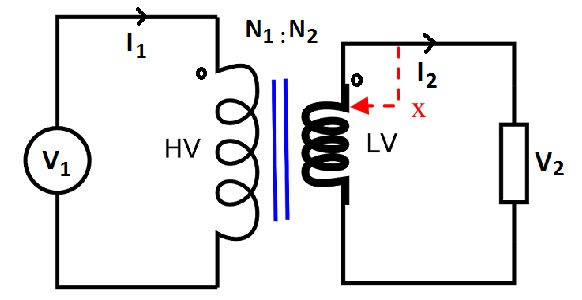

Windings

Windings are copper or aluminum conductors wrapped around the core. These windings are responsible for the actual voltage transformation through the principle of electromagnetic induction.

- Types of Windings: The windings consist of primary and secondary coils. The ratio of turns in the coils determines whether the transformer steps up or steps down the voltage.

- Their Role in Voltage Transformation: The voltage is proportional to the number of turns in the windings, allowing the transformer to convert high voltages to lower voltages or vice versa.

Types of Transformers

Different types of transformers are designed for various applications.

Step-Up Transformers

These transformers increase the voltage from the primary side to the secondary side. They are typically used in power plants where electricity is generated at lower voltages and then stepped up for transmission over long distances.

Step-Down Transformers

Step-down transformers lower the voltage from the primary side to the secondary side. These are used at the receiving end of transmission lines, where high-voltage power is stepped down to safer, usable levels for consumers.

Distribution Transformers

These transformers are used to distribute electricity to end-users in homes, offices, and industries. They operate at lower voltage levels and are designed to handle varying loads.

Detailed Construction of Transformers

The construction of transformers is a detailed process that involves precise engineering.

Construction of transformer core

The transformer core is constructed using laminated sheets of steel. This design minimizes energy losses caused by eddy currents and hysteresis, which are common in alternating current (AC) applications.

- Laminated Core vs. Solid Core: Laminated cores are preferred over solid cores because they reduce eddy current losses significantly.

Construction of transformer core

The windings of a transformer are made from copper or aluminum, with copper being the more commonly used material due to its high conductivity. These windings are insulated to prevent short circuits and are designed to withstand high voltages.

- Different Types of Conductors: Round and rectangular conductors are commonly used in transformer windings.

- Insulation Techniques: Insulating materials such as paper, oil, or epoxy are used to separate the windings and prevent electrical faults.

Transformer Oil

Transformer oil plays a dual role in cooling and insulating the transformer. It circulates within the transformer, absorbing heat and preventing electrical discharges between components.

- Maintenance Requirements: Regular testing and filtration of transformer oil are necessary to maintain its insulating properties and cooling efficiency.

Transformer Tank and Bushings

The tank houses the core, windings, and oil, protecting these components from environmental factors. Bushings are used to bring high-voltage connections into the transformer while providing insulation.

Cooling Mechanisms in Transformers

Transformers generate significant heat during operation. To prevent overheating, cooling systems are incorporated into their design.

Natural Cooling (ONAN)

In this method, the transformer relies on natural convection of oil and air to cool down.

Forced Cooling (OFAF)

Forced air and oil circulation methods are employed in larger transformers to enhance cooling efficiency.

Tap Changer in Transformer

A tap changer allows the transformer to adjust the voltage output within certain limits without needing to shut down.

Off-load Tap Changer

This tap changer can only be operated when the transformer is de-energized.

On-load Tap Changer

This type allows adjustments while the transformer is in operation, providing greater flexibility in voltage control.

Protective Devices and Accessories

Transformers are equipped with protective devices to prevent damage.

Buchholz Relay

This device detects gas generated in transformer oil, indicating possible internal faults.

Pressure Relief Device

Used to relieve excess pressure inside the transformer tank, preventing rupture or explosion.

Transformer Testing and Commissioning

Before a transformer is put into operation, several tests are conducted to ensure it functions properly. These include insulation resistance tests, voltage ratio tests, and load tests.

Common Transformer Faults and Maintenance

Transformers require regular maintenance to function efficiently. Common faults include insulation breakdown, oil degradation, and winding damage.

Conclusion

Understanding the construction of a transformer is key to appreciating its role in power systems. These devices, though often unnoticed, are essential for ensuring the electricity we rely on is delivered safely and efficiently.

FAQs

1. What is the main function of a transformer?

A transformer changes the voltage levels between circuits in an electrical system to allow for efficient power transmission.

2. Why is transformer oil used?

Transformer oil serves as an insulator and cooling agent, protecting the transformer from overheating and electrical faults.

3. What are the types of transformers?

There are several types, including step-up, step-down, and distribution transformers, each serving different voltage regulation needs.

4. How does a tap changer work in a transformer?

A tap changer adjusts the transformer’s voltage output without disconnecting the system, allowing for voltage regulation.

5. What materials are used in transformer windings?

Copper or aluminum conductors are commonly used for their high conductivity and durability.