Why Tan delta testing is done?

Tan delta test is conducted for transformer oil (read here) and also for electrical equipment like C.T, P.T, Transformers ,cables etc. Purpose of this test is to determine the condition of insulation. Insulating materials (oil and paper insulation on winding) may deteriorate due to moisture ingress, aging, mechanical stress etc. Identifying the condition of insulation is important to prevent outage of equipment, breakdown time, and potential hazards.

In most of the equipment used in high voltage system tan-delta point is in-built in the equipment for conducting this test. It is located usually in box placed on outer side/cover of the equipment. Tan delta point looks like a small nail and this point is covered by a cap which grounds it.The cap is removed for testing purpose only and it is again tightened after testing is completed.

This test measures the tangent (tan) of the angle(δ) between the resistive and reactive components of the insulation impedance.

Tanδ = (IR /IC)

How tan delta test is conducted?

It is conducted using a tan-delta test kit. The kit runs on single phase AC supply, there are two leads which comes out of this testing kit, one is called H.V lead and other is called feedback lead.

Let us understand the testing process in step wise manner :

1 .Equipment to be tested should be first disconnected by removing of jumper conductors, its insulator should be cleaned using a clean and wet cloth. Tan-delta point of the equipment must also be cleaned. It should be checked that there is no moisture in the tan-delta point area, if there is some moisture it should be dried completely using a blower. No moisture should be present in any of the test cables also, else the readings will not be accurate. Water should not be used for cleaning of Tan-delta point, it can be cleaned using petrol.

Importance of cap/cover of tan delta point:

>In case of tan-delta testing of bushings of transformer, it should be ensured that tan-delta cap/cover of all remaining bushings other than being tested should be properly closed so that it gets grounded. If any cap remains open that means that if tan-delta point remains ungrounded then tan-delta readings will not be accurate. After testing of particular bushing is completed, its cap must be tightened. In case we forget to tighten the cap of tan-delta point of CT/PT, bushings, CVT etc and charge the equipment ,it may result in abnormal chattering sound and may result in damage of the equipment.

2.Kit should be properly grounded for safety purpose. For testing of equipment other than transformer winding, HV lead of the kit is connected to primary side of the equipment ,from HV lead of the kit , test voltage is injected in the equipment and feedback lead is connected to tan-delta point which is usually located inside secondary terminal box or on outer cover of the equipment.

3.We take readings of tan delta at different voltage levels, usually at 2kv, 5kv and 10kv ,the kit also calculates capacitance of the equipment. For an ideal insulator as the insulating material is 100 % pure, the current passing through the insulator should only have capacitive component and it should behave like a pure capacitor, but practically some amount of impurity is always there so there is also resistive component of current.

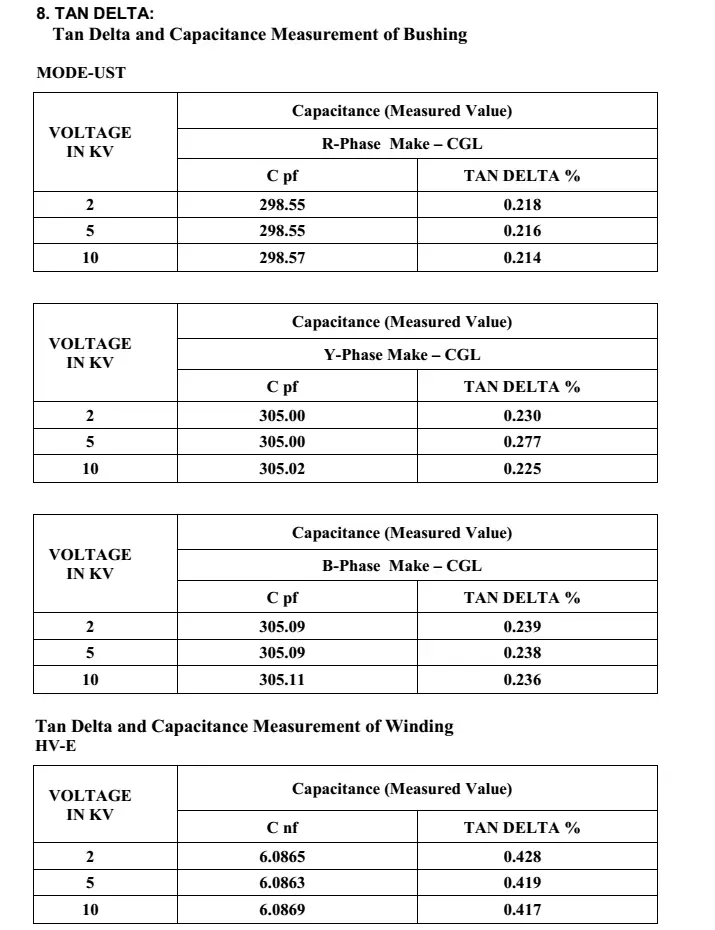

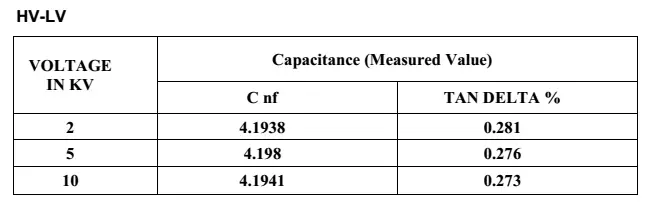

4.We consider a value of tanδ less than 0.7% to be good and acceptable.This test is conducted after specific time and present and previous results are compared, the tan delta value degrades year by year due to various reasons. Below is sample tan delta test report conducted on a power transformer. For taking tan-delta of bushings UST mode is used and for taking reading of windings wrt to earth GST mode is used.

Watch this for more info:

Common observation of above sample test reuslts:

>Tan-delta and capacitance value at all test voltage levels should be almost equal. If it is not almost equal then some error has occurred in testing. If the result is on higher side say 1% , then it should be higher for all test voltage levels. This can’t happen that readings are good for one voltage level and very poor for other test voltage.

Test modes

There are different modes given in the testing kit which are used for different purpose.

UST-Ungrounded Specimen test mode: Used for measurement of insulation in between ungrounded leads of the equipment. This mode is used when we have to test CT,CVT or Bushings.

GST-Grounded specimen test mode: In this mode readings are taken wrt to ground. This mode is used when object under test is permanently grounded. For taking readings of Hv-E and LV-E of transformer windings ,we take readings in GST mode.

GSTg-Guarded GST mode: It is used to measure the stray capacitances and separating them from basic measurement in GST mode.

GSTg=UST+GST

What should be done in case the readings are on higher side?

- Tan delta point to be cleaned using petrol and clean cloth.

- Insulator part of the equipment needs to be cleaned using wet cloth.

- It is to be checked that test cables should be free from moisture.

- In case of transformer ,oil filtration should be done properly and good values of BDV,PPM etc should be obtained.

- In case the equipment is too old and all attempts fail to give a good tan delta value, its O.E.M needs to be consulted.

Connection for tan delta test of transformer has been explained here.

Other related articles:

How are current transformers tested-08 Important tests?

Understanding Transformer Testing-09 Important electrical tests

FAQs:

- What does the Tan Delta value indicate?

The Tan Delta value provides information about the quality of the insulation. Higher tan δ values suggest poorer insulation, while lower values indicate better insulation condition. - When is the Tan Delta Test typically performed?

The test is performed during the manufacturing, commissioning, and maintenance of electrical equipment, as well as during routine diagnostic assessments to monitor the condition of insulation over time. - What are the applications of the Tan Delta Test?

The Tan Delta Test is commonly used for assessing the condition of power cables, transformers, bushings, circuit breakers, and other high-voltage equipment with insulating materials. - What are the advantages of the Tan Delta Test?

- Early Detection: It can detect insulation problems in their early stages, allowing for timely maintenance and preventing catastrophic failures.

- Early Detection: It can detect insulation problems in their early stages, allowing for timely maintenance and preventing catastrophic failures.

- What are acceptable Tan Delta values?

The acceptable Tan Delta values vary depending on the type of equipment and insulation material. Generally, lesser values than 0.7% indicate better insulation quality. Acceptable values should be defined by equipment standards or manufacturer guidelines. - Is it necessary to perform the Tan Delta Test regularly?

Regular testing is recommended, especially for critical equipment, as it helps to track the insulation’s condition and plan maintenance activities accordingly. - Can the Tan Delta Test be used for oil-filled equipment?

Yes, the Tan Delta Test is commonly used for assessing the insulation condition of oil-filled transformers and bushings, where it helps identify issues like moisture or contamination in the oil. - How this Test is conducted on site?

On-site testing involves using specialized test kit that applies high voltage at a specific frequency to the equipment under test, measuring the phase angle difference between current and voltage. The results are then compared to reference values. - Can this Test predict the remaining lifespan of equipment?

While the Tan Delta Test provides valuable data about insulation condition, it cannot predict the exact remaining lifespan of equipment. It helps in making informed decisions regarding maintenance and repair. - Is it safe to perform this Test on energized equipment?

No, it is not safe to perform on energized equipment. The equipment being tested should be properly de-energized and grounded to ensure the safety of the testing personnel.