Testing and commissioning of a circuit breaker is done in all plants before putting the circuit breaker on load i.e before start of its actual operation to ensure that it works properly as per its specification .

What is a circuit breaker?

A circuit breaker (C.B) is an electrical device which is used to break the circuit or to interrupt the flow of current during occurrence of any fault or manually when desired. A circuit breaker can not sense fault on its own , fault is sensed through protective relays and they send a signal (+Ve Dc Supply) to circuit breaker tripping coil to trip (turn off) the breaker in case of occurrence of fault.

Closing and tripping coil of a circuit breaker are identical and their purpose is to hit the desired part of breaker after they get the signal (power supply) either from protective relays or through Trip and close switch (TNC switch). Thus a tripping or closing coil is a DC operated device which mechanically hits the desired part of a circuit breaker when DC voltage is supplied across it.

Fig1-Tripping coil (PC-mevoco.be)

As soon as tripping coil gets +Ve DC voltage from any relay or TNC switch, it gets energized and it hits a specific part of the breaker which trips the breaker and breaker poles (R,Y,B) isolate and power gets cut off.

Whenever any high voltage electrical contacts open ,there will be production of arc between the contacts and to extinguish this arc ,arc quenching medium like Sf6 gas, Vacuum, Oil etc is used. On the basis of arc quenching medium ,circuit breakers are classified as Vacuum circuit breaker(VCB), Gas circuit breaker (GCB) etc.

Testing and commissioning of a circuit breaker

Following tests are conducted during Testing and commissioning of a circuit breaker :

1.Insulation Resistance (I.R) test

It is conducted using an IR tester and readings are taken when breaker pole is in open position and when breaker is in closed position. When breaker is open and breaker contacts are isolated, I.R values should be high usually in range of Giga-ohm and when it is closed I.R value should be ideally zero.

Three phase circuit breakers have three poles-R,Y & B and when the circuit breaker trips (open) ,all poles should open at once and when breaker is closed all poles should close at once, if there is mismatch in opening or closing of poles ,there will be voltage and current mismatch in the output side and will also produce heavy spark and protective relays will operate.

Also poles should open within a specified ti.se reasons, during testing and commissioning of a circuit breaker , circuit breaker timer test is also conducted.

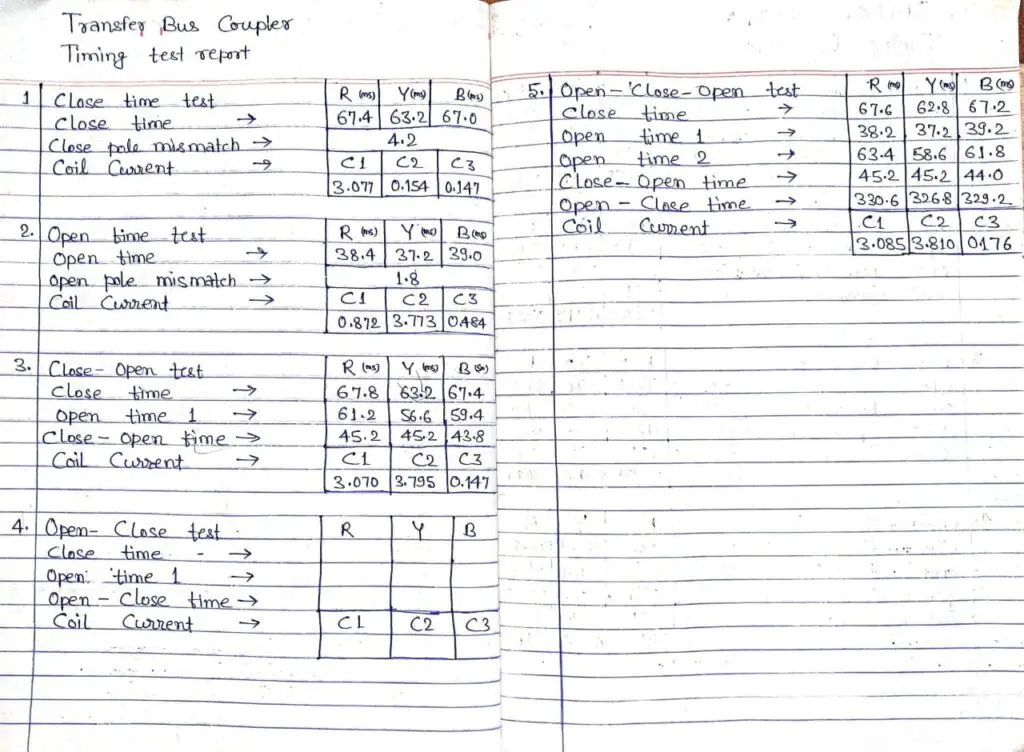

2.Circuit breaker timer test

It is used to test opening/closing time of circuit breaker and mismatch of timing of poles , this test is conducted using a Circuit breaker timer test kit. Following five types of readings are taken in the kit:

All timings in above sample report is in millisecond , ideally pole mismatch should not be greater than 05-07 ms.

>Trip and close operation of circuit breaker is checked from local (switchyard) and remote (control room) and tripping of circuit breaker on fault is also checked by creating a fault through current injection kit or through a 100w/200w test lamp. You many read about Testing and commissioning of control panel here.

3.DCRM (Dynamic Contact Resistance Measurement)

This test is conducted by using a DCRM test kit , this kit injects a 100 Amps DC current through the breaker contacts during its Close-Open (C-O) operation and measures the corresponding voltage drop at a high speed (generally at 10kHz or more).

Contact resistance testing measures the resistance of electrical connections – terminations, joints, etc. Its a test for assessing the condition of a Circuit Breaker’s main and arcing contacts. The resistance value needs to be compared with the value given by the manufacturer. The value should also be compared with previous records.

>If all above tests are found to be in order ,then circuit breaker is taken into service.

You may watch this for more info:

For understanding more about DCRM test procedure and connection click this link.

FAQs:

- Why is circuit breaker testing necessary?

Circuit breaker testing is crucial to ensure that circuit breakers operate correctly when needed. It helps identify any potential issues or faults that could affect the breaker’s performance. - What are the different types of circuit breaker tests?

There are several types of circuit breaker tests, including timing tests, insulation resistance tests, contact resistance tests, and more. These tests assess different aspects of the breaker’s performance. - How often should circuit breakers be tested?

The frequency of testing depends on factors like the type of circuit breaker, its criticality, and the manufacturer’s recommendations. In general, high-voltage circuit breakers may require more frequent testing than low-voltage ones. - What is a timing test for a circuit breaker?

A timing test measures the time it takes for a circuit breaker to open or close after receiving a signal. It ensures that the breaker operates within the specified time limits, preventing damage to the electrical system. - What is an insulation resistance test for a circuit breaker?

An insulation resistance test checks the integrity of the insulation materials within a circuit breaker. It helps identify any electrical leakage or breakdown of insulation. - What is a contact resistance test for a circuit breaker?

A contact resistance test measures the electrical resistance of the contacts in a circuit breaker. High contact resistance can lead to overheating and poor performance. - How is circuit breaker testing performed?

Circuit breaker testing is typically conducted using specialized test equipment. Testers measure various parameters and compare the results to specified tolerances or manufacturer’s guidelines. - Can circuit breaker testing be done in-house, or is it better to hire professionals?

Both options are possible. In-house testing can be cost-effective for routine maintenance, but hiring professionals may be necessary for more complex or high-voltage breakers. - What should I do if a circuit breaker fails a test?

If a circuit breaker fails a test, it should be further inspected and repaired or replaced as necessary. Failing to address the issue could lead to equipment damage or electrical hazards. - Are there standards or regulations for circuit breaker testing?

Yes, there are industry standards and regulations that govern circuit breaker testing, depending on the type and application of the circuit breaker. For example, the ANSI/NETA standards in the United States are commonly followed. - Can circuit breaker testing help prevent electrical accidents?

Yes, regular circuit breaker testing can help identify potential issues that, if left unaddressed, might lead to electrical accidents, fires, or equipment damage. It is a vital part of electrical safety and maintenance. - What are the costs associated with circuit breaker testing?

The costs of circuit breaker testing can vary depending on the type of breaker, the number of breakers, and whether testing is done in-house or by professionals. It is essential to budget for testing as part of your maintenance plan. - Is circuit breaker testing mandatory for electrical systems?

In many cases, circuit breaker testing is recommended or required to comply with safety regulations and ensure the reliability of electrical systems, especially in critical infrastructure or industrial settings. - How can I find a qualified professional or service for circuit breaker testing?

You can search for electrical maintenance or testing services in your area. Ensure that the professionals or companies you hire are certified and experienced in circuit breaker testing.