Air insulated substations(AIS) and Gas Insulated substations(GIS)

Broadly there are two types of substations : Air insulated substations(AIS) and Gas Insulated substations(GIS). In AIS all electrical equipment like CT, circuit breaker, Isolators etc are installed in the open air in the switchyard, however in GIS these electrical equipment are installed within closed chambers which is filled with SF6 gas.

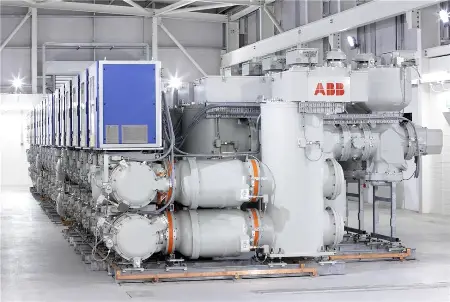

In gas-insulated substation (GIS) we use a superior dielectric gas- Sulfur hexafluoride (SF6), at a moderate pressure . Electric equipment like-circuit breaker interrupters, isolators, current transformers (CTs), voltage transformers (VTs) and conductors etc are encapsulated in SF6 gas inside metal enclosures which are grounded and all of them are placed inside a warehouse like building called as Pre Engineered Building (PEB) as shown in the picture below:

It is to be noted that some equipment like Power transformers, L.As and CVTs in GIS are installed outside in the switchyard . The atmospheric air insulation used in a conventional, air-insulated substation (AIS) requires meters of air insulation but when using SF6 gas , it can reduce this to few centimeters.

Advantages of Gas Insulated substations (GIS)

As GIS uses SF6 gas insulation which requires very less insulation compared to air therefore Gas Insulated substations (GIS) can be smaller than AIS by up to a factor of 10. A GIS is mostly used where there is space constraint or the space is expensive or it’s not available.

As most of the electric component stay within SF6 gas enclosed aluminium alloy pipes ,the active parts thus gets protected from deterioration from exposure to atmospheric air, moisture, contamination, etc. And due to this reason, GIS is more reliable, requires less maintenance, and will have a longer service life (more than 50 years) compared to AIS.

Why do we use SF6 gas?

Sulfur Hexafluoride(SF6) gas is used as arc quenching medium in high voltage circuit breakers as well as in GIS as it offers many advantages. It is an inert, nontoxic, colorless, odorless, tasteless, and nonflammable gas consisting of a sulfur atom surrounded by and tightly bonded to six fluorine atoms. It is about five times as dense as air.

SF6 gas is used in GIS at pressures from 400 to 600 kPa absolute.The pressure is chosen so that the SF6 will not condense into a liquid even at the lowest temperatures the equipment experiences. It is also to be noted that SF6 gas has two to three times the insulating ability of air at the same pressure.

SF6 gas is about 100 times better than air for interrupting electrical arcs which forms on separation and joining of electrical contacts. It is therefore the universally used interrupting medium for high-voltage circuit breakers, replacing the older arc quenching mediums of oil and air.

Limitations of a Gas insulated substation (GIS)

1. Installation and manufacturing cost of GIS is high when compared to conventional Air Insulated substations. Also GIS equipment testing and commissioning is sophisticated as compared to AIS.

2. Sf6 gas pressure is regularly monitored and it is to be maintained. Possible gas leakages can not be ruled out.Also Flash over may occur when SF6 gas pressure reduces in any module so that SF6 gas pressure is monitored in each compartment periodically.

3. Special care is taken in Gas insulated substation so that no dust particles should enter into the live compartments which may result in flash-over and thus causing a fault and power interruption.

4. When some faults occurs internally , it may take very long time to find and the diagnose the fault which can increase the power outage time.

Conclusion

Gas insulated substation has better reliability ,longer life and can be constructed within limited space but they are more expensive and sophisticated compared to Air insulated Substations.