Before we understand the difference between on load tap changer and a voltage regulator, first let’s try to understand on load tap changer and transformer taps.

What are transformer taps?

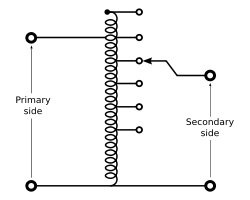

Transformer taps are positions in winding of a transformer which are used for voltage regulation ,Taps can change the number of turns in one winding of the transformer and thus can change the turn ratio and as the voltage depends upon the turn ratio, We can vary the voltage and set the tap position as per desired voltage.

There are typically two types of transformer taps:

- On Load Tap Changer (OLTC): This type of tap changer allows adjustments to be made while the transformer is energized or under load. It’s a dynamic way to control the transformer’s output voltage during varying load conditions.

- Off-Circuit Tap Changer (OCTC): This type of tap changer requires the transformer to be de-energized (made off) during the adjustment process. It is usually done during maintenance or when the transformer is offline.

On Load Tap Changer (OLTC)

On-load tap changer is an equipment attached to a transformer to vary the tap positions to obtain desired output voltage while they are On load i.e without disturbing the power flow. The on load tap changer operates by changing the tap position on the HV winding, thereby altering the turns ratio of the transformer.

Tap-changer can be internally or externally connected with transformer windings ,most common design is placing them inside the main body of the transformer. On load tap changer consists of two separate sections, they are Diverter switch and Tap selection. The diverter switch is placed inside separate housing inside the transformer and the switch is filled with transformer oil . Tap changers diverter switch look like this :

During changing of the tap from one tap position to another position, the neutral or phase connection can be discontinued for a moment. A resister unit is used in parallel with the main tap to avoid discontinuity during the changeover of the tap position. Tap is changed through a motor drive mechanism which is mounted externally on transformer body, the drive mechanism can be also moved mechanically just like spring charging in circuit breakers. Name plate of transformer has complete details regarding different tap positions and its corresponding voltages.

Normal tap: When the transformer is on normal tap ,it will step down or step-up the voltage as per its designed rating. For e.g on normal tap a 33/11kv transformer will have turn ratio of 3.0, it means if voltage in primary side is 33kv then then secondary voltage will be 11kv.

Relation between OLTC oil quality and IR value of HV-E

While testing a power transformer ,if it is observed that LV(N) to earth I.R values are good but HV (N)-Earth values are very poor ,then we must check oil of OLTC, if oil in OLTC chamber is not filtered properly then it will impact HV-E I.R values and it will be very less compared to LV-E values. Oil test of OLTC chamber is done to assess its quality.

You may watch this for more info:

Impact on DGA tests:

Acetylene is generated in the on load tap changer during tap changes as a result of arcing between the fixed and moving parts ,this gas can move in main body of transformer and may result in elevated levels of Acetylene in DGA test reports, thus old transformers can be contaminated by the OLTC gases.

How to know if tap changer is working correctly?

All equipment are first tested in its factory and then they are dispatched to sites. One of the simple test which can be done to find out if tap changer is working properly is to conduct voltage ratio test at all taps and match the results with factory test report, if the results matches then OLTC is working satisfactorily . We can also conduct winding resistance test on all taps and compare its result with factory results. Above tests are conducted with help of testing kits.

Off-Circuit Tap Changer

A basic explanation of how an Off-Circuit Tap Changer works:

- De-Energization:

- Before any tap adjustments are made, the transformer is de-energized to ensure the safety of personnel and equipment.

- Manual Adjustment:

- The tap changer is manually adjusted to the desired tap position. This is typically done using a mechanical mechanism that allows the user to select the appropriate tap.

- Re-Energization:

- Once the tap adjustment is complete, the transformer can be re-energized. The new tap setting will now determine the transformer’s turns ratio and, consequently, the output voltage.

Off-Circuit Tap Changers are commonly used in situations where it is acceptable to take the transformer offline temporarily for maintenance or adjustments. This type of tap changer is often less complex and less expensive than On-Load Tap Changers. However, the main drawback is that it requires a temporary interruption of power during the tap-changing process.

The choice between On-Load and Off-Circuit Tap Changers depends on factors such as the specific application, cost considerations, and the tolerance of the electrical system to brief interruptions during maintenance.

Voltage regulator

A voltage regulator on the other hand is basically a circuit that creates and maintains a fixed output voltage, irrespective of changes in the input voltage or load conditions. Voltage regulators are mostly used for DC/DC power conversion, but some can perform AC/AC or AC/DC power conversion also.The working principle of AC Voltage Controller is based on either of two methods: Phase Control or Integral Cycle Control and a circuit comprising thyristors are used for this purpose. Thus important difference between OLTC and voltage regulator is that voltage regulator has fixed output voltage and it takes help of electronic circuit to achieve this.

FAQs:

- What are the key components of an On Load Tap Changer?

An OLTC consists of a tap selector, diverter switch, and associated control and monitoring systems. The tap selector changes the tap position, while the diverter switch routes the current through the selected tap. - How does an On Load Tap Changer work?

OLTCs work by physically changing the connection point on the transformer winding, which alters the turns ratio and, in turn, adjusts the output voltage. The transition between tap positions is typically smooth to avoid voltage disturbances. - When is it necessary to change the tap position on a transformer?

Tap changes are made when there are variations in the input voltage or load conditions. Increasing or decreasing the tap position helps maintain the desired output voltage within specified limits. - Can tap changes be made while the transformer is under load?

Yes, that’s the primary function of an On Load Tap Changer. It allows tap changes while the transformer is energized, without interrupting the power supply. - What are the advantages of using an On Load Tap Changer?

- Voltage Regulation: OLTCs maintain a stable output voltage under varying load and input voltage conditions.

- Continuous Operation: They enable uninterrupted power supply during tap changes.

- Increased Transformer Lifespan: Proper voltage regulation helps prevent overheating and extends the transformer’s life.

- Are there any disadvantages or limitations to On Load Tap Changers?

- Cost: OLTCs can be expensive to install and maintain.

- Complexity: They require control systems and regular maintenance to ensure proper operation.

- Limited Tap Positions: The number of tap positions is finite, so the transformer may not cover all possible voltage variations.

- How often should tap changes be performed on a transformer?

The frequency of tap changes depends on the specific application and the transformer’s design. It is typically determined during the transformer’s commissioning based on load and voltage conditions. - Can On Load Tap Changers be automated?

Yes, OLTCs are often integrated with automatic voltage control systems. These systems monitor voltage and adjust the tap positions as needed, reducing the need for manual intervention. - How is maintenance and servicing of On Load Tap Changers typically performed?

Maintenance includes cleaning, inspection, lubrication, and checking for signs of wear. The frequency of maintenance depends on the transformer’s operating conditions and manufacturer recommendations. - Are there safety precautions when working with On Load Tap Changers?

Yes, working with OLTCs should be done by qualified personnel following safety procedures to prevent electrical hazards. Disconnecting power and following established safety protocols are essential.

Read here more about changing mechanism in OLTC.